Castings for Semiconductor and Liquid Crystal Production Equipment

Based on 140 years of experience in production of castings such as marine engines, Kanadevia is now expanding into castings for precision machinery such as semiconductor and liquid crystal devices.

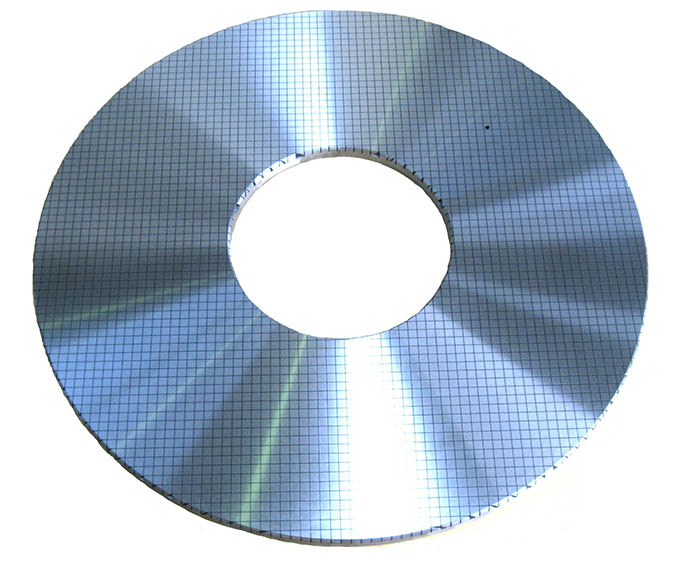

The key product in this area is lapping plates made from a specially formulated ductile cast iron that are designed to produce thinner and smoother silicon wafers, glass substrates, sapphire substrates, compound semiconductors, and other products at even higher levels of precision.

Major products

Lapping plates

Our lapping plates are designed for lapping various advanced materials that support next-generation information technology. We can provide optimum lapping grade materials tailored to customers' needs with our large selection of products.

This approach allows an integrated production process from melting and casting through to machining, which can be used in a variety of IT and precision machinery fields.

For larger dimensions, Kanadevia uses modern machine tools for precision processing to high standards of accuracy.

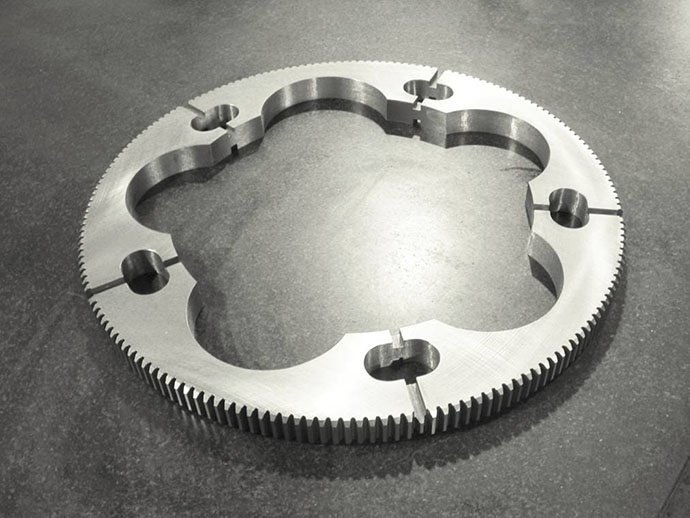

Dressing gear

Dressing gear is needed to maintain the flatness and condition of the surface of a lapping plate, and is indispensable in ensuring an even flatness of various wafers. We provide dressing gears suitable for various lapping plates.

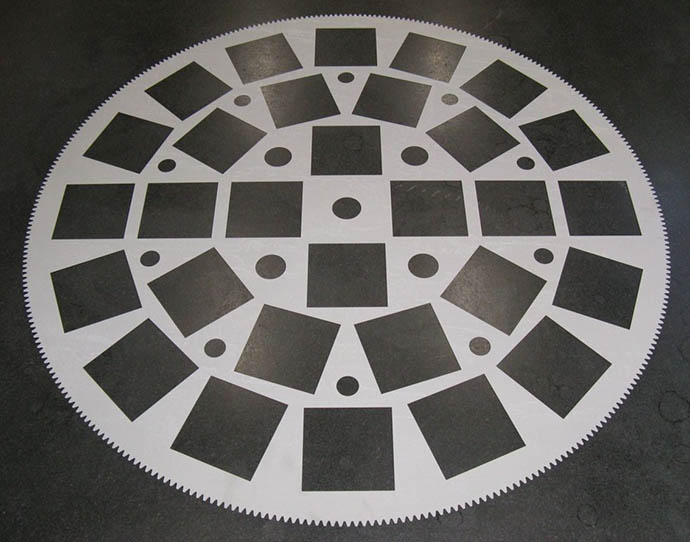

Polishing plates

High-precision polishing plates provide a mirror finish on glass substrates for liquid crystal panels, color filters, and various wafers such as silicon and compound semiconductors. We select the material and conduct surface treatment according to customers' needs.

Pad dressers

We supply carriers for holding thin substrate such as silicon wafers for the purpose of lapping and polishing. We select carrier thickness to match the work and materials, including blue steel, stainless steel, and plastic, and provide carriers suited for a range of work from our wealth of experience and technological development.

Lapping and polishing carriers

We supply carriers for holding thin such as silicon wafers for the purpose of lapping and polishing. We select carrier thickness to match the work and materials, including blue steel, stainless steel, and plastic, and provide carriers suited for a range of work from our wealth of experience and technological development.

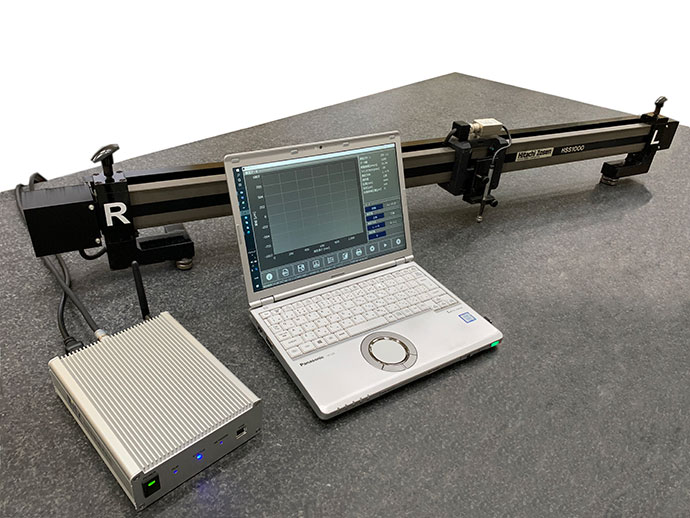

Profile measurement system

The profile measurement system is used to control the shape of lapping and polishing plates. Measurements in the upper and lower directions are possible and models measuring in length from 1,000 mm to 3,500 mm are available. As we use computers to display cross-sectional shapes that have not been seen so far, we enable effective control for improving accuracy.

Slurry recycling system

This system is used to refresh the slurry for reuse through de-ironing, filtering, classifying, and blending processes. Reusable abrasives are collected from the slurry following lapping of wafers and glass and treated as reusable slurry. By introducing this system it is possible to reduce the cost of abrasives by more than 50% (according to our survey).

Related technology

Click here for inquiries about Kanadevia technology