Plastic Film and Sheet Extruding Equipment

Product introduction video of plastic machines

The business started from a technical tie-up with Reifenhauser Inc. in 1963. We now possess a wealth of experience in all plastic extrusion fields such as food packaging materials, housing construction materials, home appliances, and industrial materials.

Kanadevia possesses a lineup of products that meet the needs of the times. We provide equipment for high-temperature super engineering plastics, equipment for high-precision optical sheets and film, etc. For the next 50 years and 100 years, Kanadevia will continue to meet the software and hardware needs of our customers by utilizing the technology and experience which we have cultivated, and by acquiring the latest technology and developing the latest equipment.

Major products

Optical film and sheet forming system

Optical film and sheet forming line/Outline of machine

- Application resin: PC, PMMA, MS, cycloolefin,PP etc.,

- Dimension of product: 100 - 1,000 µm (min. 50), maximum width: 3000 mm

- Forming speed: maximum 100m/min.

Outline of sheet molding equipment

- Application resin: PC, MMA, MS, cycloolefin, PP, etc.,

- Dimension of product: maximum thickness: 20 mm, maximum width: 3000 mm

- Forming speed: maximum 10 m/min.

Ultra-high temperature molding systems that support super engineering plastics

Outline of machine

- Application resin: Special PC, PPS, PEEK, etc.,

- Dimension of product: thickness 20 - 400 µm; width 500 mm

- Forming speed: maximum 18 m/min.

Features

- A compact design concept that is multi-functional as well as multi-purpose

- Produces a superior product with high transparency, low residual strain, and flatness

- A maximum heating temperature for the extruder, gear pump, and die head of 450°C

- The roll unit has an ultra-elastic flexible metal roll (UF roll) covering and a maximum heating temperature of 300°C

- The roll driving unit has a super-precise reduction gear system, resulting in lower vibration as well as super-smooth roll rotation

- Enables embossed or patterned finishing as well

Metal elasticity roll (UF roll)

By reducing the thickness of the metal roll comprising the outer cylinder, this proprietary development of Kanadevia enables stable roll pressure formation even under low linear pressure conditions. This makes it possible to obtain film products with high gloss, high transparency, low residual strain, and outstanding smoothness.

Both water and oil can be used as the heat medium. This technology is mainly used in the manufacturing of films and sheets for optical applications. Kanadevia also offers a lineup of ultra-high temperature UF rolls that support super engineering plastics.

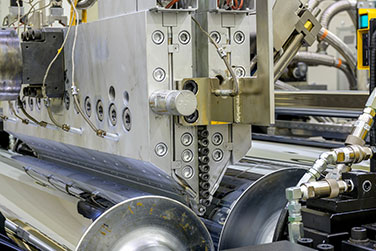

Chronodie (high-performance T-die)

The tip of the die lip is lengthened in order to improve moldability. Furthermore, the distance (air gap) between the roll crimping part and the tip of the die lip is minimized.

Features

- 1Improved thickness accuracy (both TD and MD directions)

- 2Lowered phase differences and reduced unevenness of low phases

- 3Improved yield by reducing neck-in amount

- 4Improved moldability

- 5Possible to mount a heat bolt automatic adjustment lip device

- 6Possible to install in existing facilities

Features

- 1Continuous pattern transfer both inline and offline

- 2Simultaneous transfer of multiple different sizes and pattern shapes

- 3Pattern transfer to film as small as 100 µm

- 4Compatible with both flat film and taper film

General-Purpose Film and Sheet Forming Systems

Kanadevia meets all customer needs by offering a full lineup of various molding systems such as thin-walled sheet/film molding systems, multi-layer sheet/film molding systems, and foam sheet molding systems.

Resin used

PVC, PE, PP, PS, ABS, PET, PMMA, PC

Examples of application

- 1Food packaging materials

Packaging film, lid material, food trays, cup containers, tofu containers, egg packs, etc.

- 2Home appliances

Refrigerator lining, lighting equipment, etc.

- 3Building materials

Decorative boards, floor mats, wallpaper, corrugated boards, carport seats, etc.

- 4Miscellaneous goods

Blister packs, buffers, carry bags, etc.

- 5Automobiles

Car mats, interior cushioning materials, etc.

Automation and personnel/labor saving systems

Kanadevia offers the following systems.

- 1Automatic start-up system for extruders

This automated system performs startup and shutdown procedures for the extruder from start to finish simply by pushing a single button

- 2Automatic position adjustment system for molding equipment

A system that automatically adjusts to the molding position at the time of production through simple operations based on pre-programmed production conditions.

- 3Preventive maintenance systems

A system that displays guidance on the operation screen during maintenance and issues instructions on the inspection location and contents at the time of unusual state of the equipment

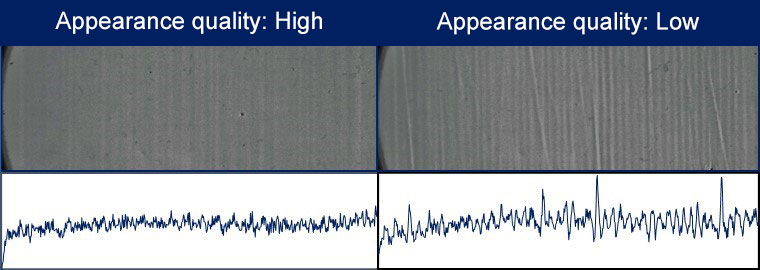

Transversal inspection device

This inspection device quantifies the appearance quality of sheets (films) for optical applications by brightness.

- Quality control and quality maintenance are made possible through digitalization

- Excel display for all information related to device operation and measurement/analysis results

- Automatic measurement of samples at multiple angles

- Supports a wide range of sheet (films) thickness

- 1Inspection sample dimensions

Height 210 mm × Width 300 mm

- 2Resolvable horizontal reinforcement interval

0.2 to 50 mm

Plastic Technical Center

The Center is equipped with a wide variety of test equipment to meet the needs of our customers.

- Equipment for single-layer/multi-layer film extrusion tests

- Equipment for single-layer/multi-layer sheet extrusion tests

- Equipment for super engineering plastic extrusion tests

- Equipment for thermal transfer tests

After service

Our after-sales service is based in Osaka, and responds to customer requests both in Japan and overseas.

Related technology

Click here for inquiries about Kanadevia technology