Deposition system for Anti-reflection and Anti-fingerprint

By combining a sputtered cathode designed by Kanadevia and the vacuum deposition method which we cultivated during the development of organic EL film deposition equipment, we provide equipment used to achieve integrated film formation in the same equipment from the formation of antireflection layer to antifouling layer, thus maximizing production efficiency.

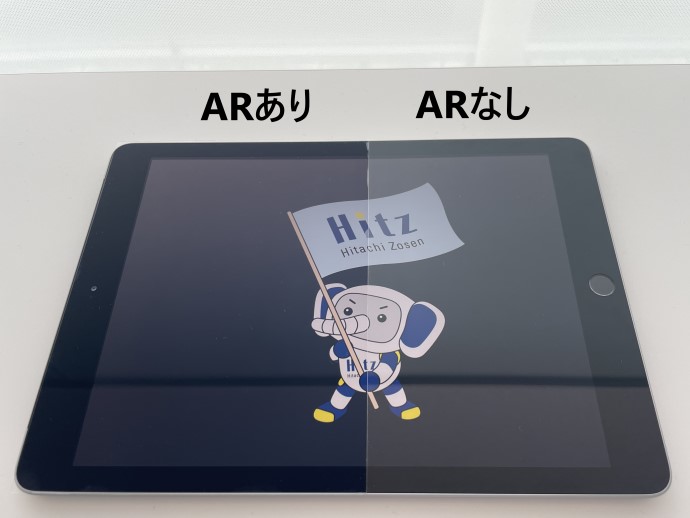

- *Anti-reflection film (AR film) is a coating intended to prevent the glare and reflection of light.

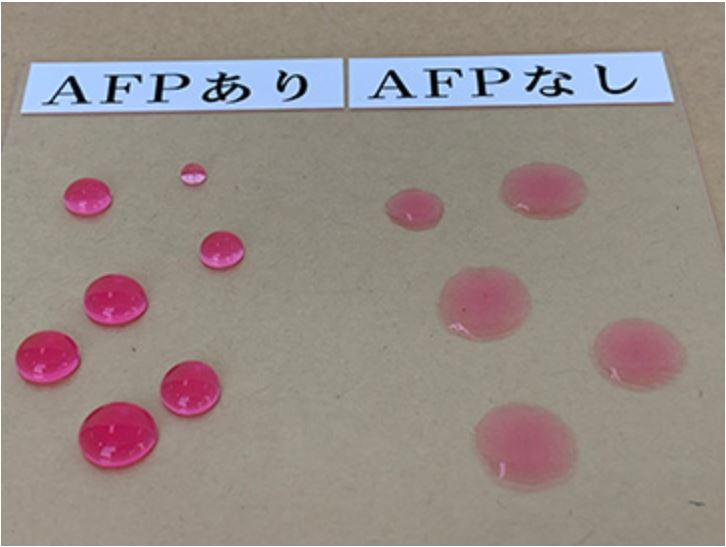

- *Anti-finger print (AFP film) is a coating that prevents fingerprints from sticking and makes it easier to wipe off fingerprints. (Generally applied on top of AR film)

The outermost surface of a display equipped with a touch panel must be resistant to fingerprints and dirt, easy to wipe clean, and resistant to scratches even when operated frequently. Satisfying these requirements was difficult when using the conventional wet coating method. However, the outermost surface (AFP film) formed by our vacuum deposition method maintains anti-finger print performance for a long time while also achieving high sliding durability. Moreover, high productivity is maintained through the roll-to-roll process.

Major products

Example of Kanadevia AR film

Example of Kanadevia AFP film

- *Kanadevia can also provide film formation samples. Please use the following inquiry form to contact us.

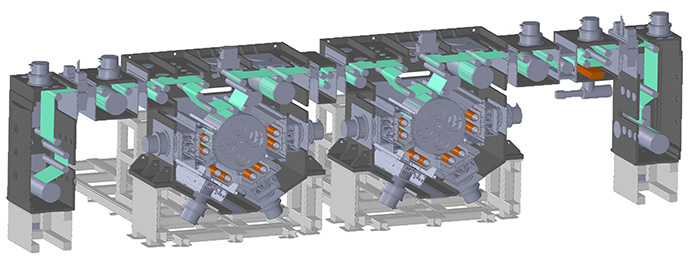

HARD-F Series

Features

This device continuously deposits AP film and AFP film on a flexible base.

- Continuous film formation is made possible by providing a differential pressure adjustment mechanism for processes with different operating vacuum degrees of sputtering and vacuum deposition.

- The AR film uses a proprietarily designed rotary cathode, which enables long-term, high-power film formation.

- By adopting a proprietarily designed nozzle-type linear source for the AFP film, we achieve both high efficiency of material utilization and highly uniform thickness during film formation.

- By adopting a proprietarily designed valve mechanism for the AFP film, we realize the following advantages: 1) Maintain a stable vapor deposition rate, 2) Close off during non-evaporation, 3) Replace material during vapor deposition, and 4) Enable vapor deposition of liquid material.

| Product name | HARD-F Series | ||||

|---|---|---|---|---|---|

| Model | HF-300 | HF-600 | HF-1200 | HF-1600 | HF-2000 |

| Supported film width | 300mm | 600mm | 1,200mm | 1,600mm | 2,000mm |

| Film feed rate | 0.5 to 20 m/min | ||||

| Film pretreatment | Plasma cleaning | ||||

| Mounted spatter source | Rotary cathode, dual cathode | ||||

| Mounted evaporation source | Nozzle linear source | ||||

| Sputter/vapor deposition pressure control | Differential pressure control | ||||

In addition, by attaching ATV mechanisms to the front and back of the device, continuous operation is possible without stopping the device when replacing the raw film, which contributes to improved productivity.

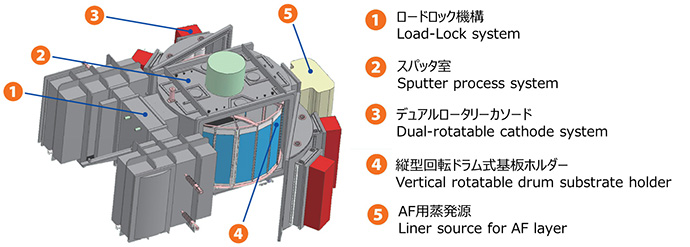

HARD-G Series

Features

This device uses a vertical rotating drum to form an AR film and AFP film on a glass substrate or plastic substrate through an integrated vacuum process.

- Equipped with a sputter source and evaporation source using the same technology as the HARD-F Series.

- Supports various types of bases such as long bases and curved bases.

- Supports film formation in a wide range of wavelengths, thus enabling flexible production for small lots of various products.

- Also, a load lock mechanism and an automatic base setting device can be installed as options.

| Product name | HARD-G Series | ||

|---|---|---|---|

| Model | HG-800 | HG-1400 | HG-1800 |

| Maximum base length (mm)* | 800 | 1,400 | 1,800 |

| Supported base materials | Film, glass | ||

| Drum rotation speed | ~100rpm | ||

| Mounted spatter source | Rotary cathode, dual cathode | ||

| Number of mounted spatter sources | 2 to 4 sources | ||

| Post-oxidation unit | Yes | ||

| Mounted deposition source | Nozzle linear source | ||

- *A base width of 400 mm can be supported by increasing the drum diameter.

Related technology

Click here for inquiries about Kanadevia technology