Hydraulic Gates

Kanadevia has a history of more than 100 years as a manufacturer of floodgates and steel pipes. We deliver a large number of gates (including high-pressure gates for dams and large river gates), penstocks, and steel pipes for installation in dams and rivers. Based on this safe and reliable construction of water gate facilities, we continue to ceaselessly develop new technology such as large flap gates for tsunami and disaster prevention, efficient management methods for existing equipment, and functional enhancement and efficient utilization through renewal (redevelopment) of existing dams and hydraulic iron pipes. Through these developments, Kanadevia aims to contribute to the further sophistication of equipment and safe land construction.

Major products

Gates for dams and rivers

This facility controls the huge amount of water and huge water pressure stored in the dammed lake. In addition to flood control, which is the main purpose of the dam, there are numerous facilities for various types of water control. Examples include flow rate adjustment for constant river flow rate, selective water intake equipment for intake of water at an appropriate temperature, and measures against turbid water in the dammed lake.

Tokuyama dam emergency flood discharge (crest radial gate)

Main spillway in redevelopment project for Amagase Dam

- Main gate (radial gate)

- 3.6 meters wide × 4.9 meters high × 9.0 meters radius

- 2 gates

- Branch pipes

- Inlet 10.3 meters in diameter (1 line)/outlet 3.6 meters wide × 5.0 meters high (2 lines)

- Total length

- 43 meters

River gate

This gate controls river water, such as estuary weirs that maintain the water level at normal times and then allow river water to flow down quickly in the event of a flood, and gutters and floodgates that intake and discharge of water from the river. There are also various other facilities such as locks that allow ships to come and go upstream and downstream of the estuary weir, fishway gates that assist fish in swimming upstream, and retarding basin locks that store river water in the event of a flood.

- Nagashima water gate (horizontal roller gate)

- 14.0 meter wide × 14.6 meters high (2 gates)

- Dotonbori river water gate

- Left: Water control gate (2-stage roller gate)

12.5 meters wide × 6.8 meters high (1 gate) - Right: Downstream lock (submerge radial gate)

9.0 meters wide × 7.1 meter radius (1 gate)

- Left: Water control gate (2-stage roller gate)

Penstock

A penstock transports water from a reservoir, etc., in a high location to a hydroelectric power plant in a low location. Since the water must drop all at once in order to generate power, the interior of the penstock is exposed to high pressure. Therefore, by connecting long distances along steep slopes, a penstock fulfills an important role for hydroelectric power generation.

- Ojiya power station, No. 3 penstock

- Design water head of 74 meters

- Extension of 78 meters

- Inner diameter 3,350 to 4,500 millimeters

- The penstock of Higashiyokoyama hydropower station

- Design water head of 119 meters

- Extension of 62 meters × 4 pipes

- Inner diameter of 1,200 to 1,500 millimeters

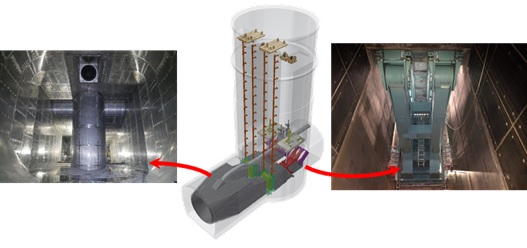

Temporary closing facility for dam renewal construction

Dam renewal work is performed while the dam is operating at a high water level. Therefore, a temporary steel lid known as a "temporary closing facility" is installed on the upstream surface of the dam body to prevent the dammed lake water from flowing out to the downstream side when drilling holes in the dam body. Kanadevia is experienced in constructing a large number of temporary closing facilities. Based on that know-how, we have developed a floating temporary closing method.

- *The floating temporary closing method is a joint patent of the Kyushu Regional Development Bureau, the Japan Dam Engineering Center, Kajima Corporation, and Kanadevia.

- Tsuruta dam upstream temporary closing facility

- For additional spillway facilities: Inner area 11.0 meters wide × 4.0 meters deep × 38.0 meters high

- For power generation and water intake: Inner area 13.0 meters wide × 3.7 meters deep × 30.5 meters high

- Floating temporary closing: Inner area 11.0 meters wide × 4.0 meters deep × 25.5 meters high

Shinemon: Hydraulic Gate Operating Status Management/Diagnostic System

Data during normal operation is automatically collected and statistically processed by software to provide a highly-reliable deterioration index. The system can also be used to investigate the cause of problems.

- Collected data

- Current value, facilities voltage, aperture, rope loosening time,rope tension

- Deterioration index

- Starting current, operating current, number of operations, operating time, start-up time, number of rope bends, rope tension, mechanical efficiency, pulley efficiency

Main Achievements

| 1975 | First visitor gate in Japan (Aji-River Hydraulic Gate-Osaka Prefecture) |

|---|---|

| 1983 | First stainless steel shell-type fixed wheel gate in Japan (Ozayahimon Central Hydraulic Gate-Kumamoto Prefecture |

| 1986 | First internal elevator facility for a dam in Japan (Tase Dam-Tohoku Regional Bureau) |

| 1987 | The world's first large-sized sediment-flushing facility, upstream on the Kurobe River, built on a JV with Mitsubishi Heavy Industries, Ltd. (Dashidaira Dam Sediment Flushing Facility-Kansai Electric Power) |

| 1988 | First stainless steel multistep straight fixed-wheel gate in Japan (Tamagawa Dam Water Intake Facility-Tohoku Regional Bureau) |

| 1989 | First temporary closing facility for dam redevelopment construction in Japan (Yoroibata Dam Temporary Closing Facility-Tohoku Regional Bureau) |

| 1994 | Japan's largest high-pressure-type radial gate, planned water depth: 115.288 m (Miyagase Dam Main Discharge Facility-Kanto Regional Bureau) |

| 2004 | Japan's largest jet flow gate, planned diameter: 2,800 mm (Surikamigawa Dam Main Discharge Facility-Tohoku Regional Bureau) |

| 2009 | Japan's largest high-pressure slide gate (Obara Dam Flood Control Discharge Facility-Chugoku Regional Bureau) |

| 2015 | Japan's first floating temporary closing facility (Construction of Tsuruta Dam Upstream Temporary Closing Facility-Kyushu Regional Bureau) |

Related technology

Click here for inquiries about Kanadevia technology