Maintenance and Earthquake Protection for Steel Structure

Many of the massive bridge stocks built during the period of high economic growth in Japan are aging, and the importance of infrastructure conservation is being highlighted once again.

Kanadevia organically integrates and utilizes technology in inspection, diagnosis, evaluation, repairs/reinforcements, and increased lifespan, all of which we have cultivated during our 140 years of history. By doing so, we will continue to contribute to society by offering a total solution business that helps solving bridge maintenance problems.

Major products

Preventive maintenance technology

Today, Japan is in an era of aging infrastructure. Consequently, it is increasingly important to perform preventive maintenance, which seeks to minimize life cycle costs and extend the life of structures by discovering damaged parts and implementing countermeasures. Based on this concept of preventive maintenance, it is necessary to incorporate the concept of asset management, and to take measures to carry out rational and efficient maintenance.

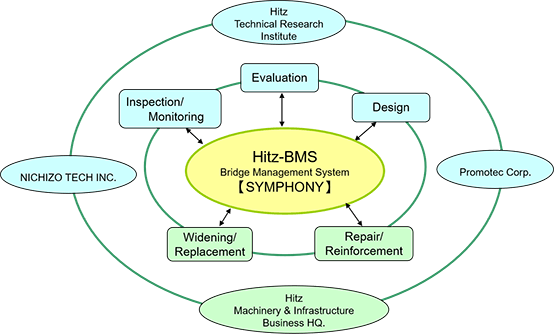

The Kanadevia Bridge Maintenance Management System is a comprehensive management system that aggregates various technologies owned by Kanadevia in order to systematize inspection, evaluation, deterioration prediction technology, and overall countermeasure construction such as repair, reinforcement, life extension, and replacement.

Technology for inspection, monitoring, and disaster prevention support

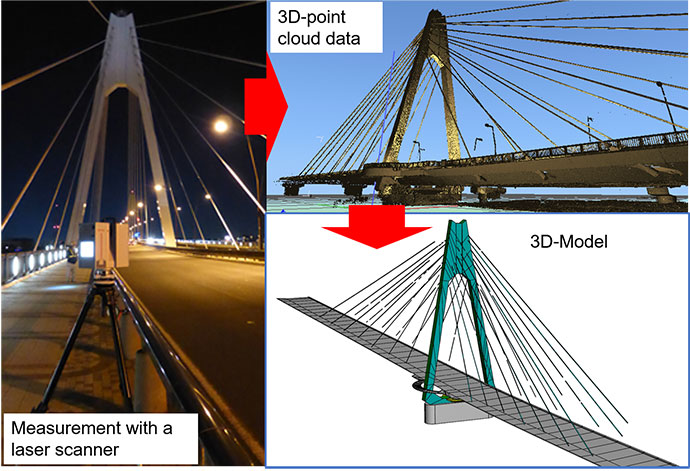

A 3D product model is used as a factory production support tool. Currently, in order to use this model for overall bridge maintenance, we are proceeding with development aimed at incorporating 3D measurement data (using devices such as laser scanners) into the product model for use as a bridge maintenance database.

We are also proceeding with initiatives to apply GPS positioning technology, which was very useful for tsunami observation after the Great East Japan Earthquake, to disaster prevention and mitigation measures. For example, the technology is used for route information management linked with GIS (Geographic Information System), monitoring of bridge soundness, and emergency notification systems in the event of a disaster.

Seismic analysis technology

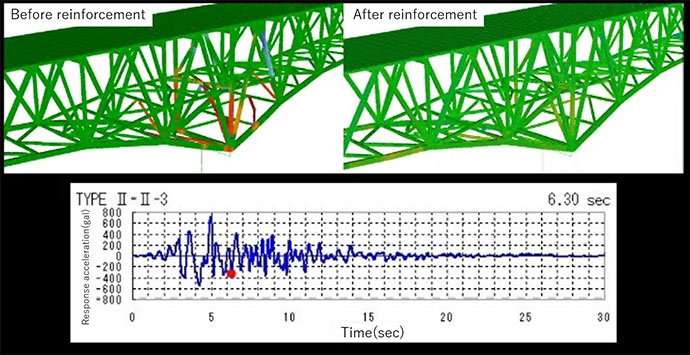

Recently, during seismic retrofitting of long bridges, there is increasing use of damage control design that reduces seismic force more efficiently through devices that absorb energy during an earthquake. Even more advanced dynamic response analysis is required.

Kanadevia possesses an abundance of dynamic response analysis technology for grasping seismic resistance. This technology can be used for all bridges from long bridges to general bridges. We also possess FEM analysis technology for use under special conditions. This technology is also used for seismic retrofitting of long bridges such as Minato Bridge, Tempozan Ohashi Bridge, and Katashinagawa Bridge.

Lifespan extension technology

Many aging bridges must respond not only to damage caused by aging, but also to environmental changes such as increased traffic volume, increased gross vehicle weight, and land subsidence. Aging bridges also require improved earthquake resistance. Seismic retrofitting, floor slab replacement, and various other lifespan extension technologies possessed by the Group are used to address these problems. In this way, the functions of aging bridges can be renovated and maintained for coming generations as important assets that contribute to society for an even longer period of time.

Lifespan extension technology is utilized in Kamome-Ohashi Bridge, which was the first bridge in Japan to have its lifespan extended by readjusting cable tension. Many other bridges have been renovated through the replacement of floor slabs.

Related technology

Click here for inquiries about Kanadevia technology