Pressure Vessels

Kanadevia supplies pressure vessels and heat exchangers to the petroleum refining and petrochemical industry, fertilizer plants, and industrial plants such as seawater desalination plants and pulp plants. We contribute to energy security through equipment for unconventional energy manufacturing plants such as refining of heavy oil, oil sands, and GTL, and other methods of responding to increasing energy demand. Moreover, in order to respond to population growth in developing countries, we help secure water and food by supplying equipment for fertilizer plants and fresh water production plants. In 2012, we established ISGEC Kanadevia Limited as a joint venture with ISGEC Heavy Engineering Limited (ISGEC), a major Indian process equipment manufacturer. By utilizing the know-how cultivated at the Ariake Plant in the joint venture, we will achieve optimal usage of ISGEC's network and accelerate business development in the Indian market. Increasing our international competitiveness in terms of cost will enable us to provide high-quality process equipment not only in India, but also in the global market.

Major products

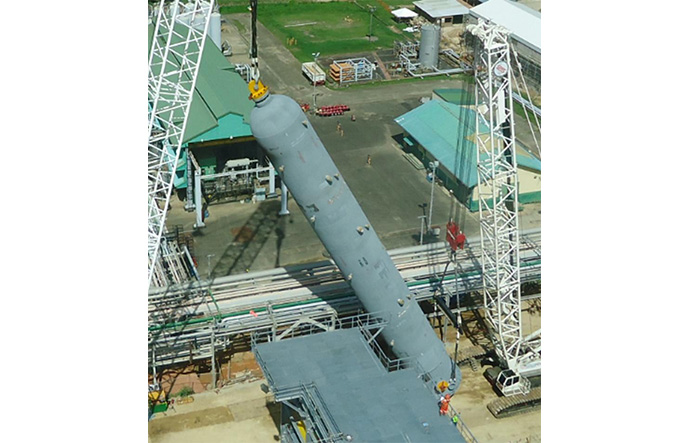

Pressure vessels

We manufacture desulfurization reactors, made from chrome molybdenum steel, which is our main product, along with CCR reactors, FCC reactors, ammonia converters, and other items.

Furthermore, we are one of the leading manufacturers of plate construction reactors with vanadium-enhanced chrome molybdenum steel. We are proud of our prominent welding techniques and process technologies that enables us to deliver high-quality reactors within a reasonable time frame.

Heat exchangers

The first Kanadevia heat exchanger was produced in 1949. Since then, we have supplied over 13,000 heat exchangers to production plants around the world, including high-pressure heat exchangers designed for specific applications such as oil refining and fertilizer production as well as large-scale heat exchangers such as methanol reactors and EO/EG reactors.

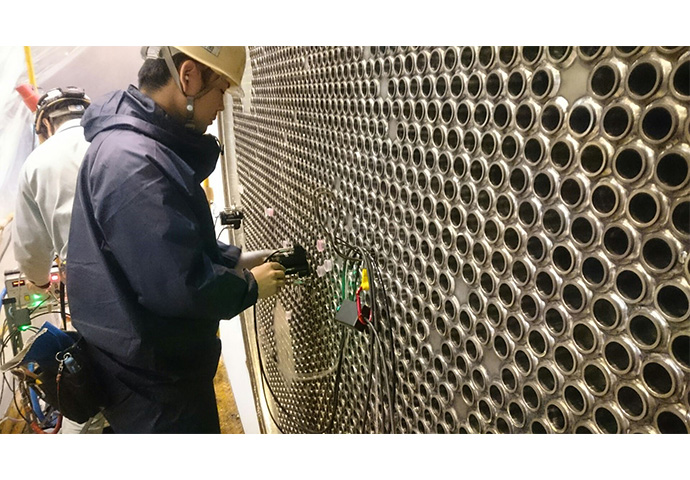

Non-Destructive Testing

Kanadevia provides a phased array ultrasonic testing system (kantanPAUT®) that accurately inspects the tube-to-tubesheet welded joints of tubular heat exchangers for flaws. We respond to customer needs such as detecting defects in tube-to-tubesheet welded joints and measuring the thinning of tubes, which is a type of inspection.

Additionally, we realized practical use of a system that automatically detects defects contained in flaw testing data by applying image anomaly detection technology that utilizes deep learning via AI (artificial intelligence) technology. We contribute to strict quality control of plant equipment by utilizing advanced inspection technology and AI technology with high judgment accuracy.

Please click below for an overview of Kanadevia's phased array ultrasonic testing system(kantanPAUT®).

Others

We manufacture FT reactors, which are the key processors in gas-to-liquid plants. We also manufacture adsorbent tower internals for paraxylene plants, as well as towers, columns, drums, and mixing vessels for various kinds of process plants.

Landfill leachate treatment system

Click here for inquiries about Kanadevia technology