Nuclear Fuel Cycling-Related Equipment

The main nuclear products of Kanadevia are transport casks and storage casks for spent nuclear fuel generated from nuclear power plants, as well as auxiliary equipment such as heat exchangers for nuclear power plants, and vessels and equipment used in reprocessing plants. In particular, we have a track record of more than 40 years in spent fuel transportation and storage casks, beginning with the development and manufacturing of the HZ-75T, our first domestically-produced product, in 1978. In 2011, Kanadevia obtained the N Stamp for containers and equipment related to nuclear facilities and equipment of ASME (American Society of Mechanical Engineers), and we will actively work on the production of nuclear equipment for nuclear power plants in the future.

Major products

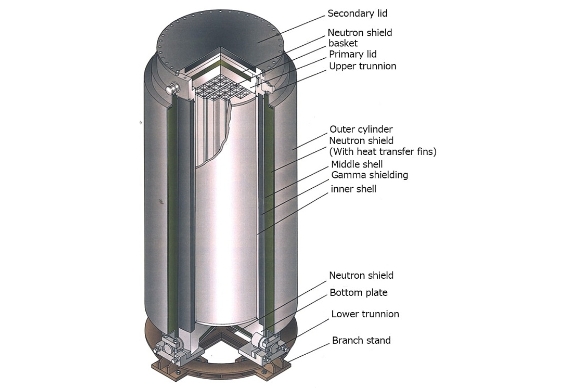

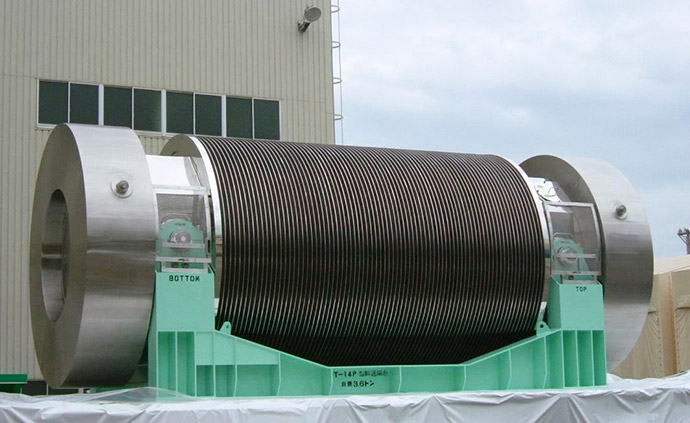

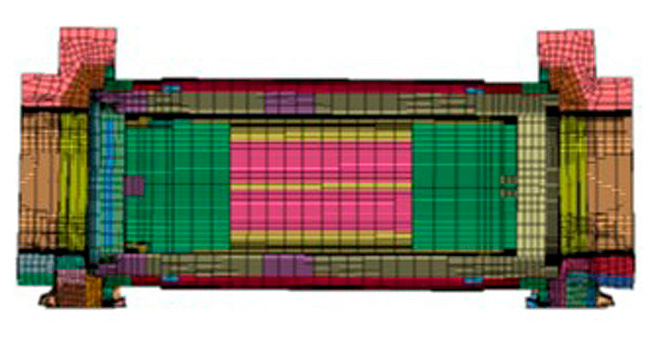

Metal casks

A cask is a container used to safely transport and store spent nuclear fuel from nuclear power plants. The term "metal cask" refers to fuel storage casks with a body made of thick metal.

Casks confine radioactive substances contained in spent nuclear fuel, and offer all the safety functions of radiation shielding, heat removal, and subcriticality in one container. Kanadevia designs and manufactures products according to customer needs, and have delivered more than 100 casks to date.

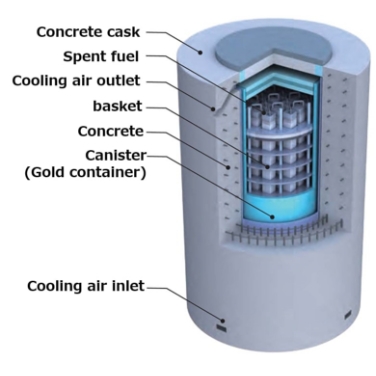

Concrete casks

Concrete casks are casks that use concrete as a shield instead of metal. Concrete casks are often used for dry storage of spent nuclear fuel in the United States. Even higher levels of safety can be achieved by storing spent nuclear fuel in a weld-sealed metal canister, which is then stored inside a sturdy concrete cask.

The Group provides everything from design to manufacturing. Currently, we mainly supply our products to power plants in the United States in collaboration with our group company NAC International. Thus far, we have delivered about 600 concrete casks.

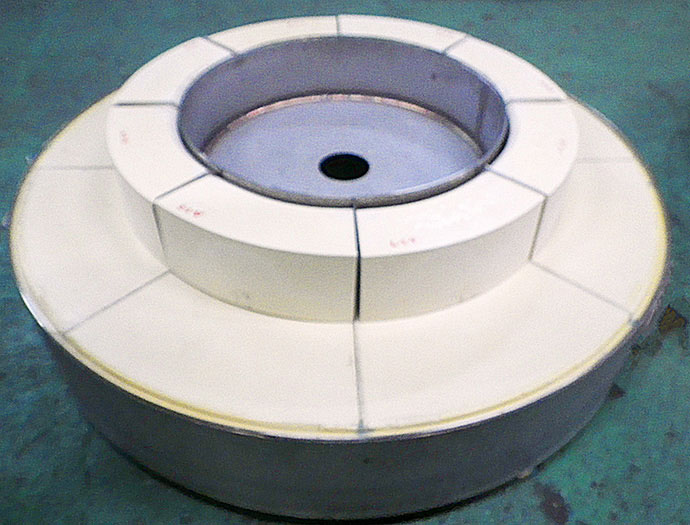

Neutron shielding materials

Kanadevia holds licenses for six types of neutron shielding materials including NS-4-FR. We sell these materials worldwide through domestic licensees and our group company NAC International in the United States. Neutron shielding materials are used for the lids, bottoms, and body interior of casks in order to block neutron rays emitted from spent nuclear fuel. NS-4-FR is an epoxy-based solid resin that is a leading type of neutron shielding material. NS-4-FR is easier to handle than liquid shielding materials such as water and can be used at high temperatures. Therefore, in addition to being used in Kanadevia's casks, it also has a record of use around the world.

Research & Development

R-PUF buffer

When transporting radioactive materials in a metal cask, a buffer (a can body filled with cushioning material) is attached to the cask to prepare against an accident during transportation. Conventional buffers use wood such as balsa as a cushioning material. However, from the viewpoint of resource conservation, Kanadevia is developing Rigid Polyurethane Foam (R-PUF) as a buffer replacement for wood.

The density of R-PUF is easily controlled, so the shock absorption capacity can be improved through optimal design for each cask. Additionally, the construction period is shorter because the drying work required for wood is no longer necessary.

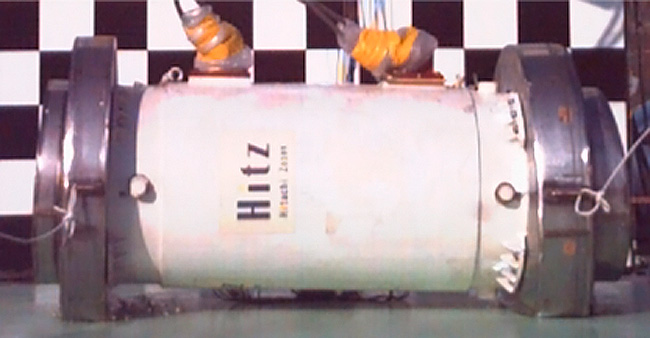

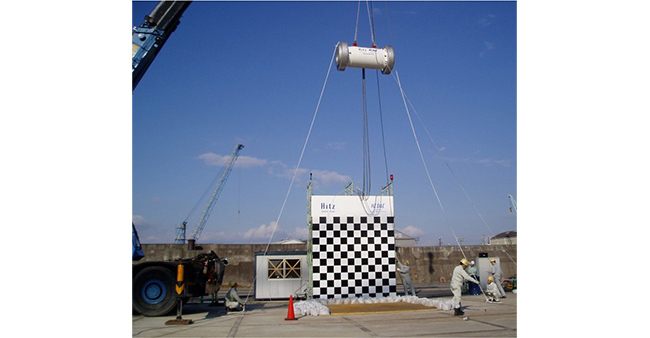

Drop test

When designing a cask, we evaluate safety by performing numerical analysis assuming accidents during handling and transportation. Additionally, we perform a drop test using a 1/3 scale model and then compare the test results with the analysis. This process confirms the soundness of the design.

We also conduct drop tests of casks using an R-PUF buffer. Through these tests, we have confirmed that R-PUF has the necessary shock absorption capacity and possesses a high level of safety to prevent accidents involving spent nuclear fuel.

Related technology

Click here for inquiries about Kanadevia technology