SCR (Selective Catalytic Reduction) NOx Removal System

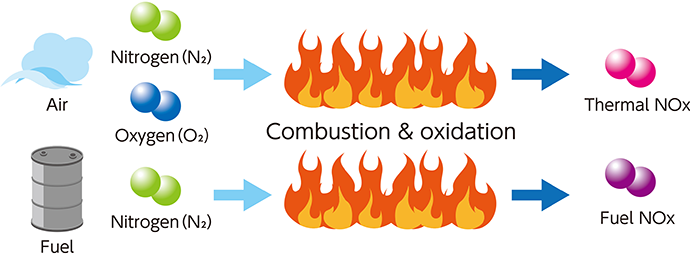

When exposed to the strong ultraviolet rays of the sun, nitrogen oxides (NOx) contained in the exhaust gas emitted from the chimneys of factories and power plants generate photochemical oxidants and PM2.5 particles. These substances are harmful to humans and plants. Furthermore, NOx causes a chemical reaction in the atmosphere to become nitric acid. Nitric acid oxidizes lakes, rivers and soil. It also causes acid rain, which adversely affects plants and organisms. Kanadevia provides denitration catalysts and denitration systems that decompose this NOx by reacting it with ammonia to make it harmless. By doing so, we contribute to the reduction of air pollution.

Major products

Denitration system

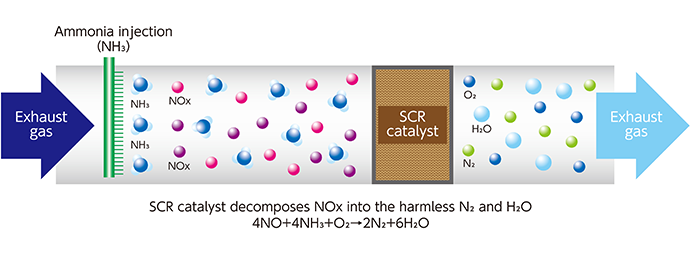

Nitrogen oxides (NOx) are contained in combustion gas emitted from fixed facilities such as thermal power plants, refuse incineration power plants, and chemical plants, and from marine diesel engines. We react NOx with ammonia to decompose them into nitrogen and water, thus making them harmless and reducing NOx emissions.

System components

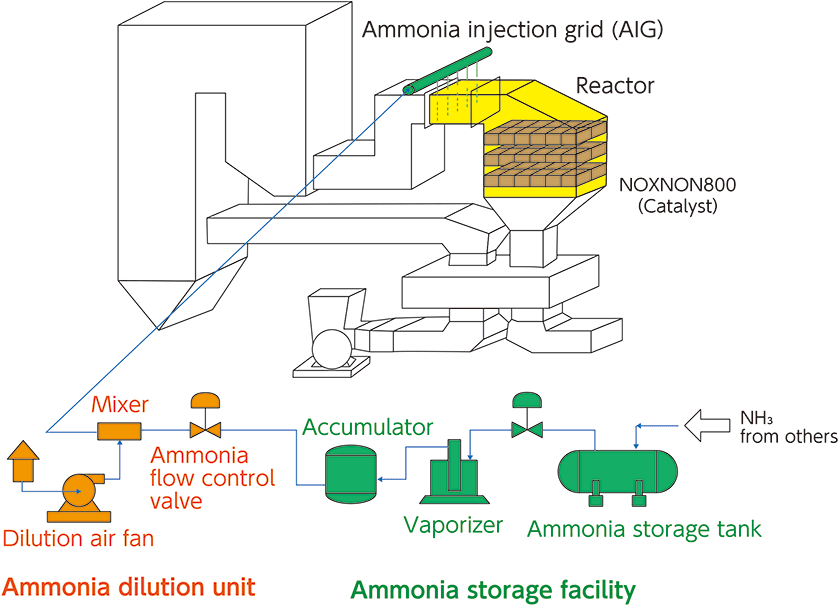

The denitration system consists of a NOx-removal catalyst, denitration reactor, ammonia injection system, ammonia dilution system, and ammonia storage and supply tanks.

NOx-removal catalysts

Kanadevia started developing the denitration catalyst in 1969 and commercialized it in 1973. We made various improvements to realize our current product NOXNON 800, which we have supplied since 2016. We supply NOXNON800 not only in Japan but also in the United States, China, and other parts of the world.

Characteristics of catalyst (NOXNON800)

- 1Compatible with a wide range of reaction temperature

- 2Compatible with a wide variety of fuel types

Performance

Major records of delivery

Kanadevia provides denitration catalysts and denitration systems in a variety of fields such as gas turbines, various boilers (coal-fired and crude oil-fired, etc.), diesel engines, refuse incineration power generation facilities, ethylene cracking furnaces, petroleum reformers, and sintering furnaces. Since delivering our first unit in Japan in 1974, we have delivered more than 580 units in countries such as the United States, China, South Korea, Taiwan, Saudi Arabia, Qatar, etc.

Related technology

Click here for inquiries about Kanadevia technology