Marine Growth Prevention System (MGPS) for ships

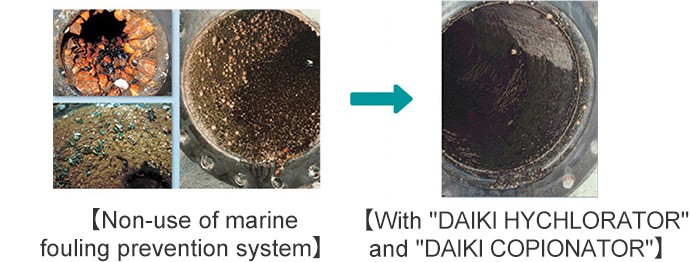

With over 2,000 systems sold since 1967, marine fouling prevention systems, "DAIKI HYCHLORATOR" and "DAIKI COPIONATOR", are well proven their effectiveness and reliability.

Marine organisms may cause the clogging of seawater systems, such as piping, condenser or cooler, by growing and adhering to their inner surface.

"DAIKI HYCHLORATOR" and "DAIKI COPIONATOR", by our proven technology, will prevent marine organisms from growing or adhering on the inner surface of seawater systems.

Major products

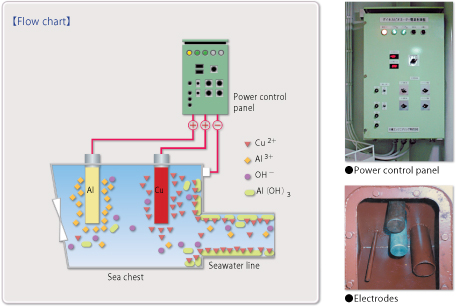

DAIKI COPIONATOR (Marine fouling prevention systems - copper ion type)

DAIKI COPIONATOR generates copper ion and aluminum ion by electrolysis, and form fouling prevention film on the inner surface of seawater systems.

There are two versions of DAIKI COPIONATOR, "Electrolysis cell type" - inject copper ion into sea chest - and "Sea chest type" - place copper and aluminum electrode inside sea chest directly.

- 1Low power consumption (compared with sodium hypochlorite injection system)

- 2High efficiency by fewer ion injection without seawater pollution worries.

- 3Electrodes can be replaced by crew (Electrolysis cell type)

- 4Only few daily maintenance - just check voltage and electric current displayed.

- 1Generation of copper ion

Copper ion comes out of the copper metal (anode) by passing the direct current.

- Anode reaction Cu → Cu++e-

- 2Form of fouling prevention film

Aluminum ion comes out of the aluminum auxiliary electrode by passing the direct current. Aluminum ion is oxidized by dissolved oxygen and pH in seawater into Al(OH)3.

Al(OH)3 makes the surroundings filled with copper ion that keep off the marine organisms.- Anode reaction Al → Al3++3e-

- Cathode reaction 3H2O+3e- → 3/2H2+3OH-

- Colloid formation Al3++3OH- → Al(OH)3

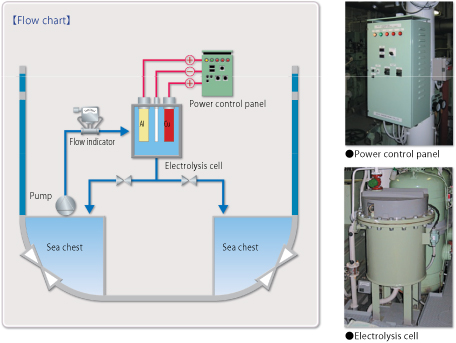

DAIKI CAPIONATOR - Electrolysis cell type

DAIKI CAPIONATOR - Sea chest type

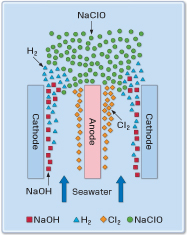

DAIKI HYCHLORATOR (Marine fouling prevention systems - sodium hypochlorite type)

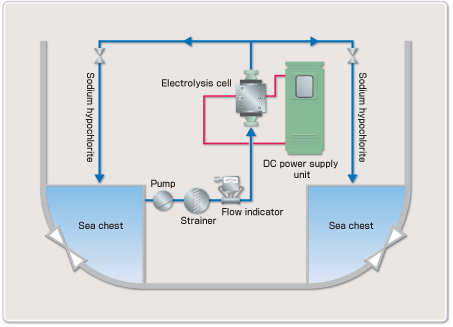

DAIKI HYCHLORATOR injects sodium hypochlorite generated by electrolysis into sea chest, in order to prevent marine organisms from growing or adhering on the inner surface of seawater system.

- 1Reduced maintenance cost - Our own developed electrode lasts long.

- 2Easy operation - No need of attendance during operation.

- 3Adjustable treatment capacity.

- 4Harmless to the human body - Sodium hypochlorite is widely used for public water system.

DAIKI HYCHLORATOR generates sodium hypochlorite from seawater by electrolysis. When electrolyze seawater (pH 8, Salinity 3% - average), sodium hypochlorite (NaClO) is produced by the following reaction.

- Total reaction

NaCl+H2O → NaOCl+H2↑ (Sodium hypochlorite)

- Anode reaction

2Cl- → Cl2+2e-

- Cathode reaction

2Na++2(H++3OH-)+2e- → 2(Na++OH-)+H2↑

- Reaction in electrolysis cell

2(Na++OH-)+Cl2 → NaCl+NaClO+H2O

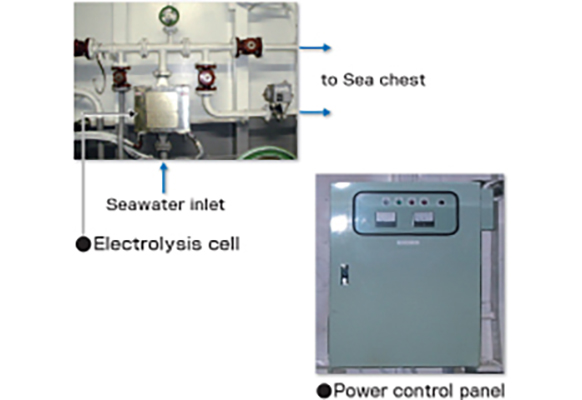

DAIKI HYCHLORATOR for large vessel

DAIKI HYCHLORATOR for small vessel

Flow chart

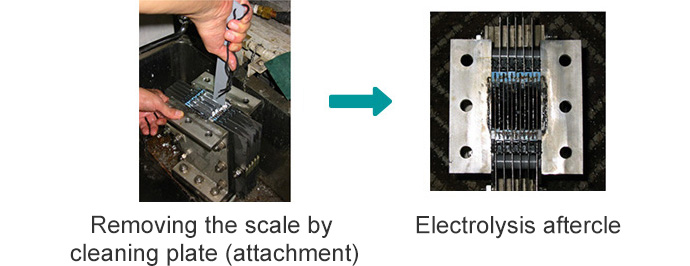

Easy maintenance

Our electrolysis cell does not accumulate scale (Ca and Mg) by patented technology, so that all you need for maintenance is to remove the scale only once a year without usage of chemicals (such as hydrochloric acid).

Related technology

Click here for inquiries about Kanadevia technology