Electron beam sterilization systems and Deep-UV systems

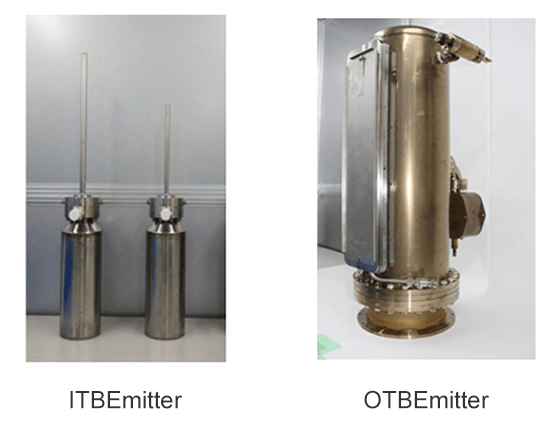

Kanadevia proposes a system that uses an electron beam irradiator (emitter) for sterilization of food and beverage containers, and for sterilization in the fields of regenerative medicine and pharmaceutical manufacturing. Our emitter illuminates only the surface of the object with low energy, so it has nearly no effect on the base metal. According to the shape of the object, two types of emitters are available: ITB and OTB. Additionally, the electron beam emitter has a compact design that is smaller than a high-energy electron beam irradiator. Furthermore, certification as a Senior (First class) Radiation Protection Supervisor is not required. The device is easy to install and is priced affordably.

Moving forward, Kanadevia will continue to increase usage in the pharmaceutical field and expand applications such as surface modification of plastic films.

Major products

Electron beam tab sterilizer

Features

This device uses two OTB emitters to emit an electron beam that sterilizes the outer surface of pharmaceutical packaging containers (tab). Sterilization performance is (SAL) 10-6 or higher, and the device is designed to minimize manual labor. Kanadevia proposes a new overall system including existing vials, connections to syringe filling lines, and filling machines. We have installed an electron beam tab sterilizer in machinery at our Chikko Plant (Taisho Ward, Osaka). The sterilizer is used for test irradiation and sample provision as a means of confirming performance.

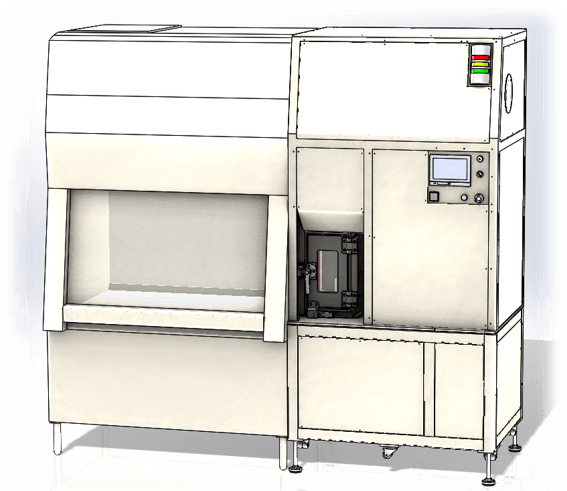

Electron beam sterilization pass box

Features

Previously, when materials were brought into isolators and safety cabinets, the outer surface of the materials was cleaned with alcohol and sterilized with hydrogen peroxide gas. However, sterility cannot be guaranteed by wiping with alcohol. Furthermore, sterilization using hydrogen peroxide gas takes time and residue is a concern. These issues have been problems in the fields of medicine and regenerative medicine. Kanadevia manufactures and sells electron beam sterilization pass boxes that use low-energy electron beam emitters to achieve exterior sterilization of various materials in about five minutes.

Indoor airborne virus countermeasures: ACSTERIA, a space sterilizer using deep UV LEDs

ACSTERIA is a commercial-use space sterilizer that uses deep ultraviolet LEDs to sterilize 99.9% of airborne viruses.

Space sterilization is possible in a short time that is difficult to achieve when using general air purifiers. For example, at maximum air volume, ACSTERIA achieves 99% sterilization of a space with a floor area of 100 m2 (about 60 tatami mats) in approximately 50 minutes.

Overview

In recent years, infection control is indispensable in spaces where many people gather. ACSTERIA is a commercial-use space sterilizer developed for hospitals, public facilities, nursery schools and kindergartens, schools, emergency evacuation sites, etc.

This machine uses a fan to intake air with a fan and then uses a deep ultraviolet LED to irradiate the air, thus sterilizing microorganisms and pathogenic viruses. Kanadevia has obtained demonstration results showing that deep UV LED achieves 99.9% reduction of viruses with high UV resistance. Additionally, we are conducting joint research and verification with universities on various pathogenic viruses that are a subject of concern in our daily lives.

Features

- 1Performance

High-grade machine: Has a maximum air volume of 28 m3/min. Sterilizes a space with a floor area of 230 to 250m2 using only deep UV LED.

Standard machine: Has a maximum air volume of 12 m3/min.

Sterilizes collection surfaces in a space with a floor area of 100 m2 using HEPA filter collection and deep UV LED. - 2Ease of use

Uses long-life LED and can operate continuously 24 hours a day for approximately 2 years

- 3Safety

Does not generate toxic gas (ozone gas, etc.)

Related technology

Click here for inquiries about Kanadevia technology