Electronic Boards and Units

By utilizing manufacturing technology of marine equipment which we have cultivated over many years, Kanadevia offers products with high environmental resistance that can be used with peace of mind in various fields.

In addition to our own products, Kanadevia also provides flexible support for contract development, trial production, mass production, and replacement of old models. In this way, we propose solutions that meet the needs of our customers.

Solution proposal

Consistent support from development to mass production

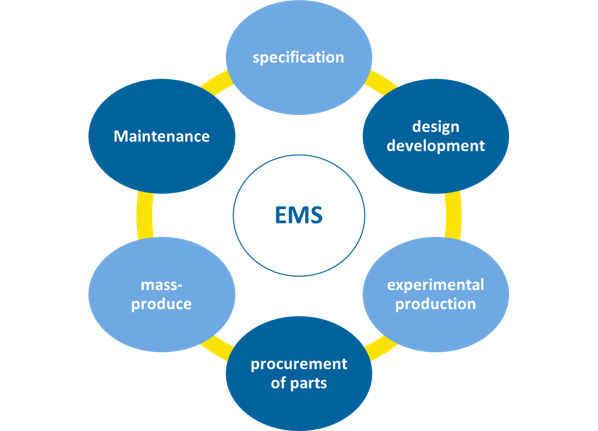

- We handle everything from development and design to prototyping, parts procurement, board mounting, and unit assembly.

- We also support EMS (Electronic Manufacturing Services).

Example) FPGA development, software development, contract manufacturing, etc.

Achieve long-term stable supply of products

Kanadevia achieves long-term stable supply of products by adopting module products such as COM-Express, changing to substitutes for discontinued products, and revising boards.

Reduce the hassle of procurement

- Regardless of mass production or prototype products, Kanadevia can handle the quantity and lot desired by customers.

- After consulting with the customer, we manage the parts inventory or finished products and deliver them according to the desired lead time.

Major element technology

Results for development of CPU boards

- SOC: Renesas RZ/RX/SH/H8 Series, Zynq (Xilinx) mounted board

- IPCore: Board mounted with NIOS2

- CPU board mounted with COM-Express

Compatible with various custom modules

- We can develop PLC modules that meet customer needs.

- Development of a module compatible with MicroTCA standards.

Achievements of general-purpose communication standards

EtherCAT, CC-LINK, FL-NET, CAN, DeviceNet, Optical communication (SFP), LCD (HDMI/DVI), Ether-net

In-house protocol communication

We support customer-specific protocol communication, develop custom communication protocols, and propose optimal suppression technology

Example: For IJ printer data, high-speed data transfer, bus extension high-speed data transfer, and TOSLINK (optical communication)

Software support

Linux, µITRON, VxWorks, Windows *We have an extensive record in real-time OS

Compatible with AI/IoT

- Respond to and realize various customer needs for visualization from the viewpoint of electronic board development.

- We are also able to construct an AI analysis system and provide data after analysis.

Environmental resistance technology

- Kanadevia possesses various test equipment and can perform product environment tests.

(Noise measurement and visualization support, static electricity tests, vibration tests, constant temperature/humidity tests, heat cycle tests) - Dust-proof and drip-proof coding is supported.

- Kanadevia has an extensive record in applications that require environmental resistance, such as for railroad vehicles and ships.

Manufacturing

Major facilities

| Name of facilities | ||

|---|---|---|

| Ultra-low humidity cabinets | Leaded automatic soldering equipment | Lead-free automatic soldering equipment |

| Surface mounting line | Base washer | V-groove dedicated board cutter |

| Cutout board cutter | Visual inspection equipment | Point solder |

| BGA rework equipment | Automatic point solder | Coating equipment |

| Thermal impact tester | Thermostat | X-ray observation device |

| Vibration tester | Nitrogen generator/air compressor | Reflow checker |

| Desktop automatic vacuum packing machine | ||

Factory features

- The factory provides integrated support from parts procurement and board mounting to unit assembly at our domestic factory.

- The factory possesses a board cleaning device and can perform flux cleaning. (Migration prevention device)

- The factory possesses a substrate coating device and can apply a coating on the board to prevent moisture and dust.

Supported models: Taffy (made by Asahi Kasei), Pelgan Z (made by the former Dow Corning) (other models can also be considered) - Both eutectic solder and lead-free solder can be produced.

Eutectic solder: Heat cycle resistant solder Lead-free solder: SAC305 - In-house inspection standards (established based on IPC-A-610 Class 2) are determined and applied, and production based on customer standards is also possible.

- Holds the external certification IPC-A610 CIT (trainer) and IPC-STD001 CIT (trainer)

Factory information

Example

Examples of customization

Example 1: Example of base replacement

Requirements

Since many parts of old models have been discontinued and it is difficult to continue settlement of payments, it is necessary to change the parts and continue production.

Themes

- Discontinued production of CPU

- Discontinued production of controller ICs such as PCI, PanelLink, HDLC, DDS, etc.

- End of OS support

Development Content

- Adopt the latest CPU

- Use FPGA to realize functions such as PCI, PanelLink, HDLC, DDS, etc.

- Change the OS

Merits

- Enables continuous production while retaining existing functions

- Achieves high-speed processing and space saving by adopting the latest parts

- Functions can be added by saving space

Example 2: Example of carrier board creation

Requirements

Develop a carrier board that has Com-Express as a core and possesses the required I/F

Development Content

Develop terminals and devices with the following specifications

(Main Specifications)

- SATA

- LVDS, eDP

- Touch panel

- PCI-Express

- LAN, Wi-Fi

- USB

- Support for Microsoft Windows 10 IoT Enterprise

Merits

- Adopting Com-Express for the core circuit significantly shortens the period until mass production.

- Flexibly supports the I/F required by customers.

- Even if the CPU is discontinued, continuous production is possible by replacing the module.

Example 3: Product development case for industrial buses

Requirements for developed equipment

We have developed CPU boards and slave boards equipped with the industrial buses requested by our customers.

Industrial bus with track record

- EtherCAT

- DeviceNet

- CC-Link

- PowerLink

- *Various industrial buses can be used upon request.

Our product case

Example1:Battery management unit

Product Details

Equipped with a lithium-ion iron phosphate battery, the battery features safety, long life, and high output.

Product Features

- Adopts a network configuration with a high degree of freedom by combining battery unit distributed arrangement, parallel (current), and series (voltage).

- Extensive connection interfaces with peripheral devices.

- Centralized management of data from multiple battery units ensures battery protection and safety.

- Battery unit parallel configuration achieves both large capacity and BCP support.

Function

- Battery protection function (voltage monitoring, temperature monitoring)

- Battery status monitoring function (cell-to-cell voltage balance correction, bank-to-bank voltage balance correction, charge amount/deterioration estimation)

Usage Examples

- Transportation Forklifts, golf carts

- Transport Refrigerated containers

- Stationary equipment Power storage device for factories/detached buildings

Example 2: Panel computer

Product Details

We developed a panel computer for our agricultural machinery guidance system with automatic steering. We can also customize the panel computer for in-vehicle use according to customer needs.

Product Features

- Uses COM-Express.

- Vibration resistance, impact resistance, and noise resistance that operate safely even on a tractor.

- Can be equipped with a 1-frequency or 2-frequency GNSS unit.

Related technology

Click here for inquiries about Kanadevia technology