Zeolite Membrane Separation System "HDS"

Major products

What is Kanadevia Corporation Membrane Separation System (HDS)?

What is Kanadevia Corporation Membrane Separation System (HDS)?

Zeolite Membrane System is eco-friendly equipment in the chemical industry

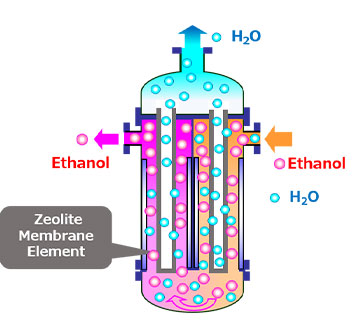

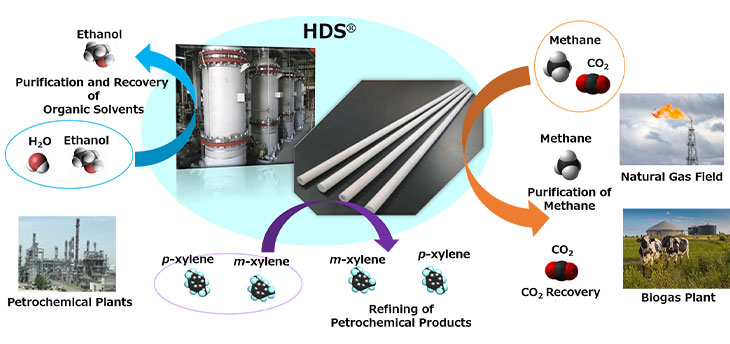

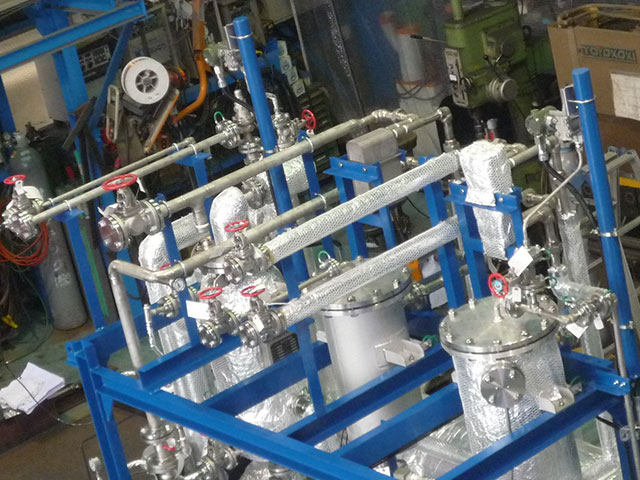

Membrane separation system is the energy-saving separation and refining technology of the most interest in recent years. Kanadevia Corporation provide membrane separation system installed own original zeolite membrane element. It is possible to be separated target component from various mixed gas and contributed for energy-saving in refinery process.

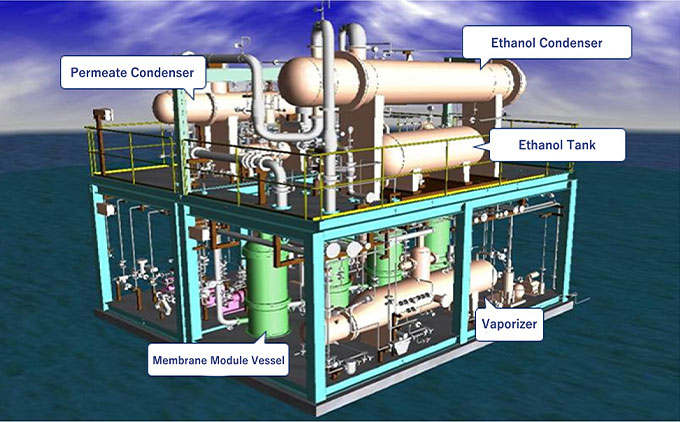

System

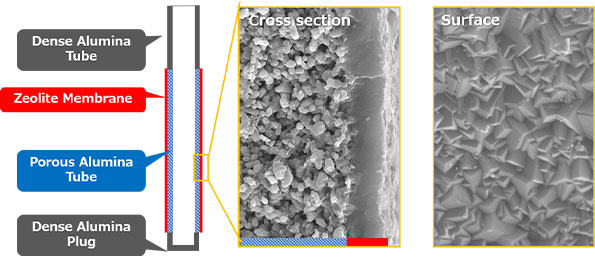

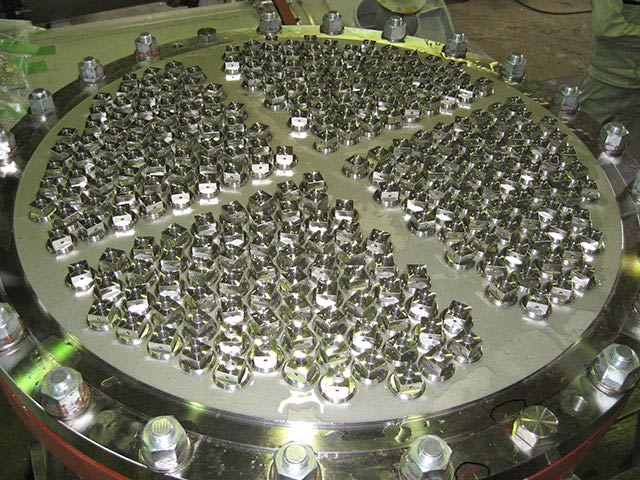

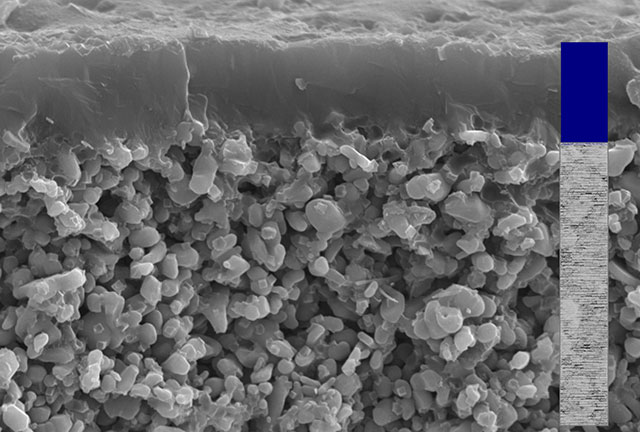

As a result of making full use of own technology, it has been succeeded in thinning zeolite which is one of functional materials. Utilizing the properties of zeolite, impurities can be removed from mixed fluid (liquid and gas) and so the target component is refined.

Only keeping the pressure difference between outside and inside of the membrane, the target molecules can be refined selectively and continuously. The component wanted to permeate can be controlled by chemical composition and type of zeolite, and operating conditions.

The separation of components proceeds by “Molecular Sieving Effects” and “Preferential Adsorption Effects”. “Molecular Sieving Effects” is the molecules lager than zeolite pore cannot be permeate the membrane and “Preferential Adsorption Effects” is that easily adsorbed on zeolite surface preferentially permeate through the membrane.

Basic Design

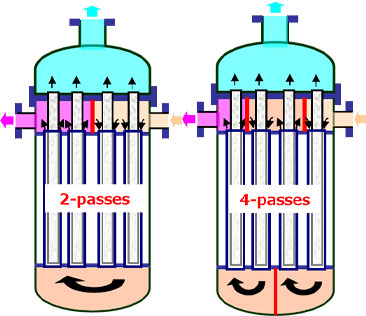

Kanadevia Corporation propose various refining system by zeolite membrane depending various mixed fluid (liquid and gas).

Applications

- Removal of water from mixed liquid contained water and alcohol

- Recovery of mixed methane from gas contained CO2 and methane

- Collection of the isomers of hydrocarbons separately

Separation System

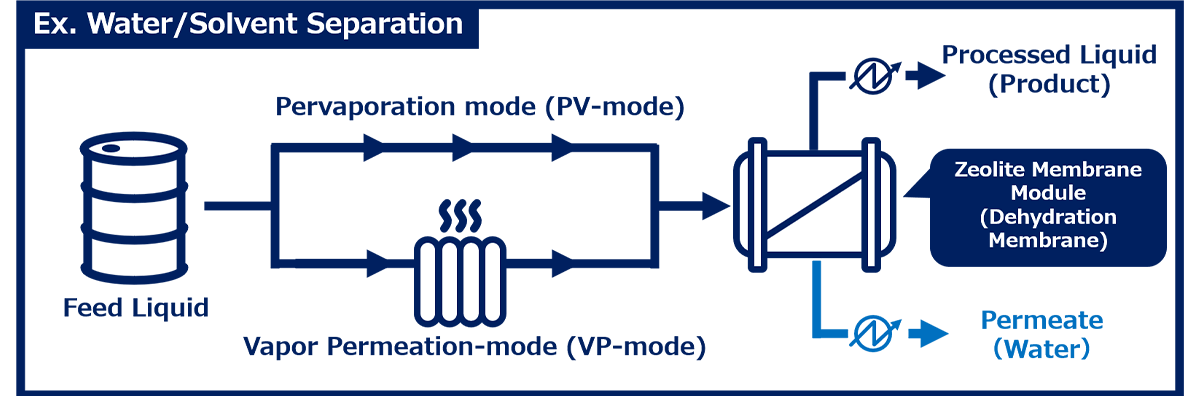

Solvent recovery adapts mainly 1.Pervaporation (PV) or 2.Vapor Permeation(VP). Kanadevia Corporation propose the best system according to Physical properties of FEED..

| Point | Remove water from FEED as liquid |

|---|---|

| Advantage |

|

| Point | Remove water after vaporized FEED |

|---|---|

| Advantage |

|

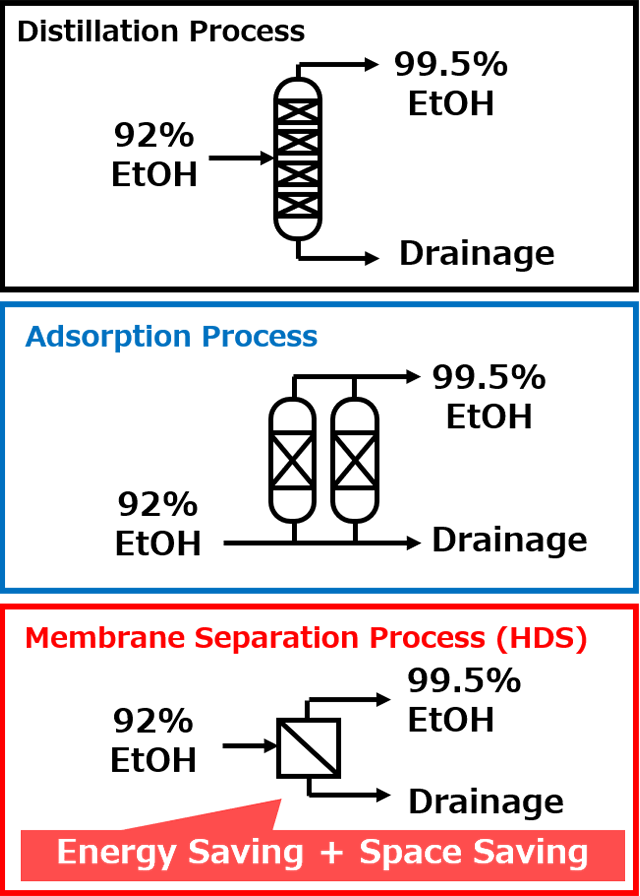

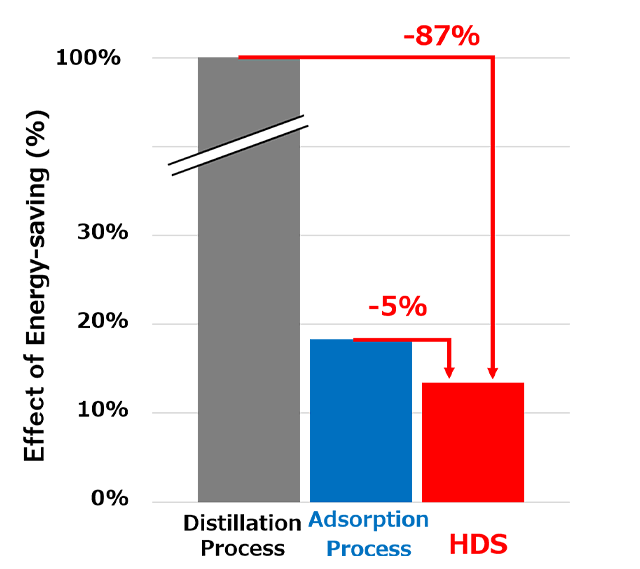

Advantage of installing HDS

- Membrane separation process is achieved significant energy-saving and space-saving compared to conventional methods such as distillation and adsorption method. At not only new plant, but also at retrofit of existing plant, it can be expected significant running cost-saving.

- “Uncomplicated operation according to process simplification, and Compact facility”

- “Waste liquid-saving, solvent purchase-saving”

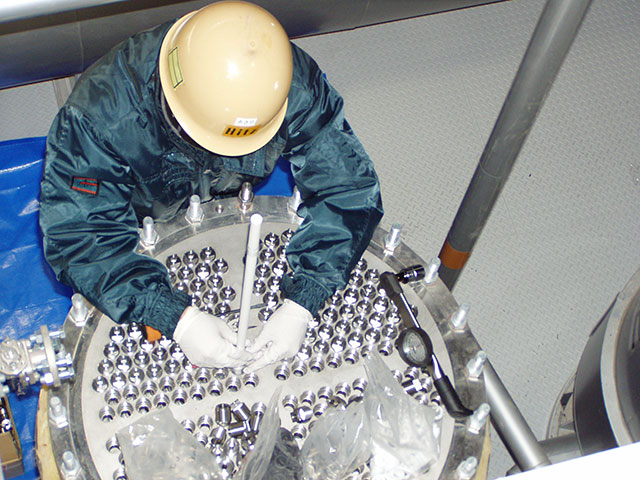

After-sales service after install

HDS is the product operating long-term.

We provide each service to bring out the equipment greatest potential.

- During commissioning: support to operate

- Preventive maintenance: regular checking and overhauling

- Post maintenance: Supply parts and maintenance etc.

Related technology

Click here for inquiries about Kanadevia technology