Hitachi Zosen Corporation and Pola Chemical Industries will join forces to develop environment-friendly cosmetic containers and raw materials - The Applications of the "Eucommia Elastomer", a plant-derived biopolymer

Mar 16, 2020

Hitachi Zosen Corporation (Head Office: Osaka City, Osaka Prefecture, Japan; Chairman and President: Takashi Tanisho) and Pola Chemical Industries (part of the Pola Orbis Group) (Head Office: Yokohama City, Kanagawa Prefecture, Japan; President: Kazuya Kugimaru), will start in March 2020 the joint development of cosmetic containers and ingredients using "Eucommia Elastomer". The aim of the collaboration, is to use plant-derived ingredients to commercialize products with low environmental impact.

"Eucommia Elastomer" extracted from tochu tea trees

"Eucommia Elastomer" is a 100% plant-derived biopolymer*1 extracted and refined from fruits of a deciduous tree, Tochu (Eucommia ulmoides), which produces the Tochu tea. Among its properties, this biopolymer has high flexibility, impact-resistance, and is a water repellent; Hitachi Zosen has been developing it as a new functional material for a variety of applications.

*1) A compound similar to plastic and resin, but made from a living organism

Applying the same materials to both cosmetic containers and raw materials for cosmetics for the first time in Japan

The "Sustainable Development Goals" proposed by the United Nations in 2015, are expected to address environmental issues, such as CO2 emissions and plastics pollution. In this sense, taking advantage of the characteristics of plant-derived "Eucommia elastomer," Hitachi Zosen and Pola Chemical Industries, will work to develop environment-friendly containers, as well as cosmetic ingredients.

- 1Utilization as an environmen tally-friendly container returning to the nature

- 2Utilization as a cosmetic ingredient with high sense of skin

This is the first joint-development in Japan to apply environment-friendly plant-derived ingredients to both cosmetic containers and raw materials.

"Impact resistance" as a container and "beauty effect" as a cosmetic ingredient

Generally, plant-derived biodegradable*2 plastics tend to possess low impact resistance. However, mixing the plant-derived biodegradable plastic (PLA) with a 5% of "Eucommia Elastomer" increases its impact resistance in 2.4 times. Additionally, the waterproofing function of the "Eucommia Elastomer" is comparable to that of high-density polythylene. Hence, these features will enable the production of biodegradable containers with excellent strength.

Finally, "Eucommia Elastomer" has a remarkable flexibility, so compared to conventional materials, it is expected to produce a pleasant feeling on the skin.

*2) The property of eventually decomposing into water and carbon dioxide by the action of microorganisms in the nature

Since 1985, Pola Orbis Group is addressing environmental concerns; to reduce the waste produced by its products, the group is selling cosmetics with refillable containers.

By introducing the use of plant-derived materials through this joint development, Hitachi Zosen and Pola Chemical Industries aims to support sustainable societies by developing cosmetics that customers want, and at the same time reducing its environmental impact.

Supplementary materials

"Eucommia Elastomer"

"Eucommia Elastomer" is a trans-polyisoprene biopolymer, with a molecular weight of over 1 million dalton, extracted and purified from the herbal tree Eucommia ulmoides (the source of Tochu tea). This biopolymer has a proven record, being used as a material filaments for 3D printers and golf balls.

Since 1986, Hitachi Zosen has been developing products using the E. ulmoides from China. In recent years, the company is working to develop new functional materials under the support of the New Energy and Industrial Technology Development Organization (NEDO), a national research and development corporation, and the Japanese Science and Technology Agency (JST), through an industry-academia collaboration with Osaka University.

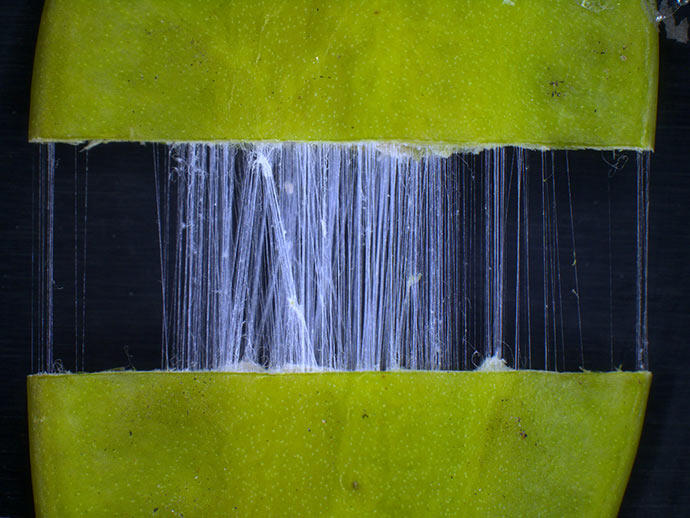

"Eucommia Elastomer" is made from the E. ulmoides pericarp, which is cultivated in China. White fibrous materials are generated and accumulate in the plant's pericarp tissue. This white material is a biologically synthesized trans-polyisoprene. Hitachi Zosen, in its Maizuru facilities, is using its own technology to produce and supply "Eucommia Elastomer" with low environmental impact.

contained in E.ulmoides pericarp

refined into granules

Pola Chemical Industries

The Pola Chemical Industries was established in 1929, and is responsible for the research, development, and production of the Pola Orbis Group. Based on research strategies determined by Multiple Intelligence Research Center of the Pola Orbis Holdings, the Frontier Research Center creates technologies such as new active ingredients, as well as creating values that transcends the boundaries of cosmetics.

Pola Chemical Industries website

http://www.pola-rm.co.jp/en/index.html

Pola Orbis Holdings website

https://www.po-holdings.co.jp/en/index.html

- Contact: Pola Orvis Holdings Corp. Corporate Communications Division

- Public Relations Tel:+81-3-3563-5540/Mail:webmaster@po-holdings.co.jp

Hitachi Zosen Co., Ltd.

Hitachi Zosen was founded in 1881. Based on the corporate philosophy of "We create value useful to society with technology and sincerity to contribute to a prosperous future", Hitachi Zosen aims to become a "Solution Provider to Create a Recycling Society", with the environmental, energy and water fields as our core business domains.

Hitachi Zosen website

https://www.hitachizosen.co.jp/english/

- Contact : Hitachi Zosen Co., Ltd. Publicity and IR Section

- (Osaka) TEL:+81-6-6569-0005 / (Tokyo) TEL:+81-3-6404-0802