Developed Second-Generation Marine SCR System (Hitz HP-SCR Mk-Ⅱ): 40% more compact than older models for easier layout planning in ship engine rooms

May 16, 2019

Hitachi Zosen recently launched the Hitz High Pressure SCR Mk-II (or Hitz HP-SCR Mk-II; hereafter, the "Mk-II"), the second-generation marine SCR (Selective Catalytic Reduction) system to reduce NOx (nitrogen oxide) emissions from marine diesel engines during ship operation.

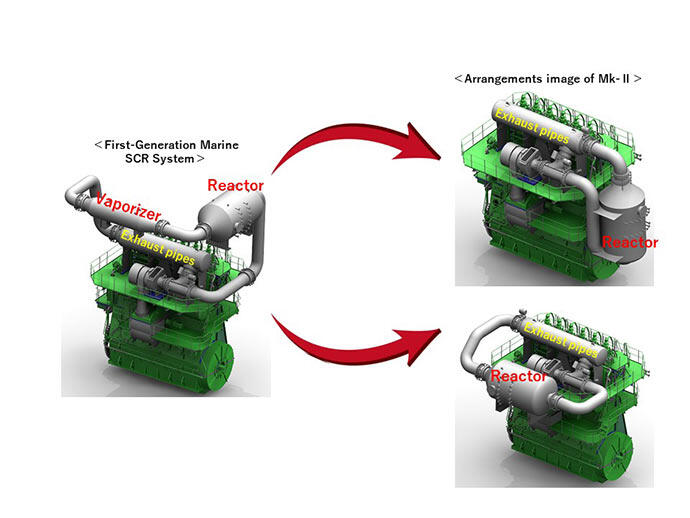

SCR is a technology that separates NOx into nitrogen and water by spraying waste gases containing NOx with urea water and passing them through a NOx removal catalyst. Previous marine SCR systems had two major elements: a vaporizer to turn urea water into mist and steam, and a reactor to react the waste gases misted with urea water with the NOx removal catalyst.

The new Mk-II no longer requires a vaporizer, as the processes of urea water spraying and steam generation and so on are now done within the engine's exhaust pipes, allowing the device to have a footprint that is around 40% more compact. This means that it is easier for shipbuilders to plan the layout of the engine room, allowing use in a range of ship types. In developing this technology, practical trials were held using a multi-cylinder test engine (4S50ME-T) at Hitachi Zosen's Ariake Works from January 2018 to February 2019, which confirmed both that denitrification performance could be ensured under the harsh conditions when the reactor is directly connected to the exhaust pipes, and the optimal position, form, etc. for spraying urea water within the exhaust pipes.

In 2014, Hitachi Zosen was the first company in the world to get FTA (First Time Approval) for marine SCR systems used in marine engines by marine engines licenser MAN Energy Solutions SE (Germany), which boasts what is overwhelmingly the world's largest market share. A total of 37 orders have been received to date, but as marine engines include marine SCR systems, installing them the old way in ship engines rooms was difficult in terms of space, so making them more compact (saving space) became a key point. The development of the Mk-II was designed to respond to these demands from ship owners and shipbuilders, and is the result of Hitachi Zosen being able to utilize both its marine engine technology and its denitration system/catalyst technology.

At present, the Tier III NOx emission standards of the IMO (International Maritime Organization) only apply to ECAs (Emission Control Areas) in North America and other areas, but the scope of ECAs is expected to expand: for example, at the 71st IMO Marine Environment Protection Committee meeting in 2017, the North Sea and the Baltic Sea were designated to be included as ECAs from January 1, 2021.

Hitachi Zosen will actively contribute to the SDG climate change measures through the development and expanded sales of marine SCR systems.

- *Tier III NOx emission standards

The third tier of standards related to NOx emissions during ship operation as set by the IMO. Tier III requires a further 80% reduction over Tier I, which came out in 2005. Tier III was enacted on January 1, 2016.

End of Document