Slaked Lime Dry Scrubbing Fly Ash Recirculation&Waste Incineration Facility Wins Japan Machinery Federation Chairman's Award for Energy-Efficient Machinery&Systems:Recognized for its ability to both effectively process flue gases and generate electricity

Feb 08, 2019

Hitachi Zosen Corporation's Slaked Lime Fly Ash Recirculation & Waste Incineration Facility was awarded the Japan Machinery Federation Chairman's Prize in the 2018 (39th) Energy-Efficient Machinery & Systems Awards from the Japan Machinery Federation.

Reason for winning

The waste flue gas generated when waste is incinerated includes hazardous materials such as acidic gases, and these are processed using self-regulated values that are stricter than those stipulated in the Air Pollution Control Act.

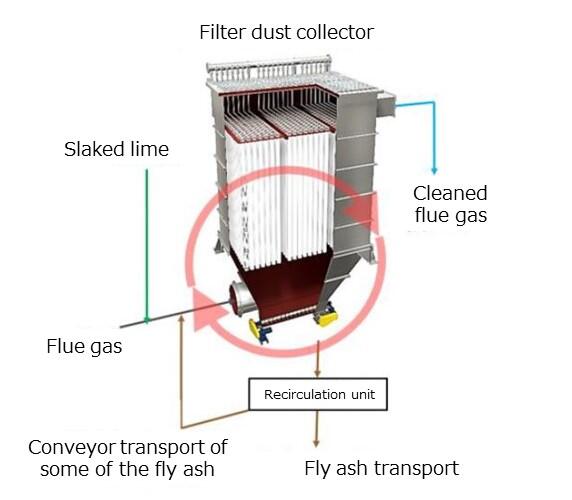

The fly ash recirculation system using slaked lime developed by Hitachi Zosen is a system that can efficiently remove acidic gases such as sulfur oxides and hydrogen chlorides contained in flue gases from energy-from-waste facilities (see diagram on right). By recirculating the fly ash, which includes unreacted slaked lime, we can reduce the amount of slaked lime required to scrub the acidic gases and the amount of fly ash for landfill disposal, helping to relieve the burden on the environment. In addition, it is possible to use with facilities using the same strict self-regulated values of no more than 10 ppm concentration of sulfur oxides and hydrogen chlorides that were conventionally treated using the older wet scrubbing method.

In slaked lime dry scrubbing fly ash recirculation waste incineration facilities that adopt this fly ash recirculation system using slaked lime in place of the wet scrubbing method, it should be possible to increase the amount of power generated by 2,553 MWh/year and improve revenue 1.4 times (total of construction costs and operational revenue over a twenty-year period) compared to previous wet scrubbing systems (Hitachi Zosen figures) if an energy-from-waste facility with a treatment capacity of 500t/day is used. The environmental effects from this sort of effective energy use were recognized in the award of this prize.

Track record and future outlook

This dry scrubbing fly ash recirculation system using slaked lime will be used at seven facilities currently under construction by Hitachi Zosen. Energy-from-waste facilities require efficient power generation and reduced environmental burdens, and the Hitachi Zosen Group actively proposes facilities that use this system as a way to contribute to the effective use of energy and to reduce environmental burdens.

In addition, along with aiming to provide clean energy through high-efficiency power generation from waste incineration and achieve our business goal of becoming a solutions provider that will bring about a recycling society, we shall contribute to achieving the SDGs (Sustainable Development Goals).

About the Energy-Efficient Machinery & Systems Awards

This is an awards scheme provided by the Japan Machinery Federation. It is awarded to companies or corporate groups that are recognized as contributing to the promotion of the efficient use of energy through the development and commercialization of superior industrial-use energy-efficient machinery and systems. Particularly energy-efficient machinery and systems are selected for and awarded the Minister of Economy, Trade and Industry Award, the Agency for Natural Resources and Energy Director's Award, or the Japan Machinery Federation Chairman's Award. Starting from FY1980, this has been carried out every year as the Energy-Efficient Machinery Awards, but from FY2018, the name was changed to the Energy-Efficient Machinery & System Awards.